Geared drilling machine with thread tapping unit and electrically controlled spindle sleeve feed DH 35V with continuously adjustable speed control.

Facts that impress in terms of quality, performance and price

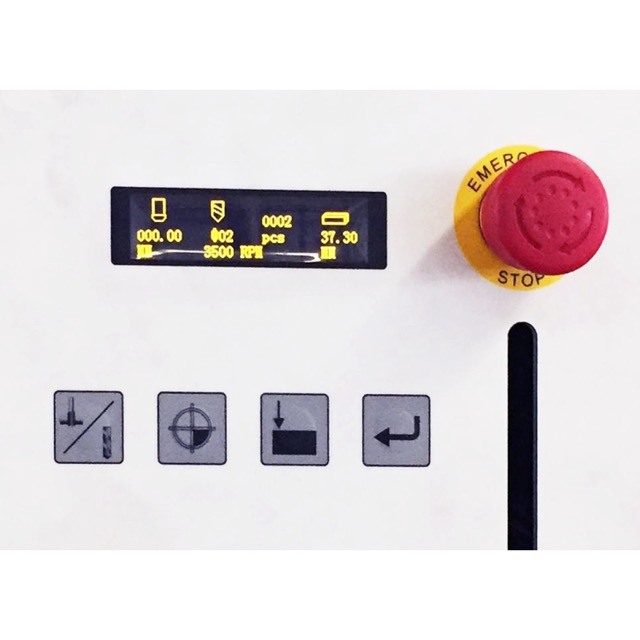

- Dirt/water-resistant, easy-to-clean membrane keyboard

- 24 V DC electronics

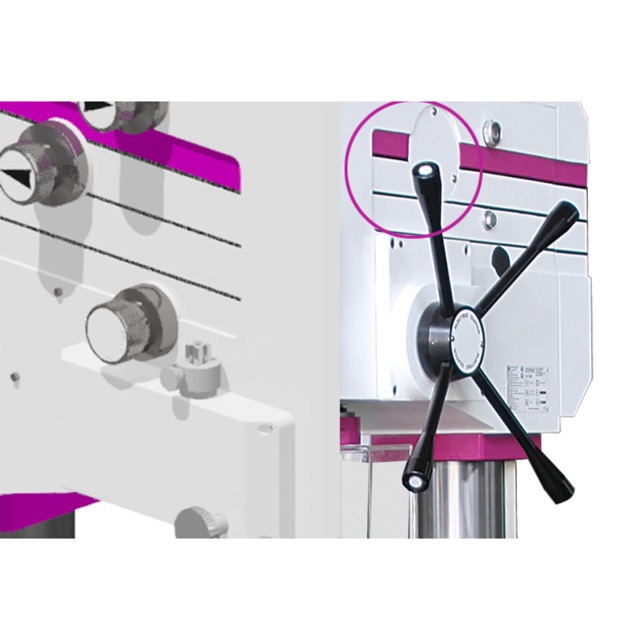

- Electrical spindle sleeve feed

- Drilling depth stop

- Low-maintenance gear unit running in a closed oil sump

- Thread tapping device.

- Machine lamp integrated in drilling head

- Main switch

- Generously dimensioned, height adjustable protective screen with safety switch for greatest possible user protection

- Generously dimensioned, solid drilling table, precision workmanship, with 2 diagonal T-slots and recirculating coolant duct, strong reinforcing ribs on rear side and double clamping

- Coolant unit with coolant tank integrated into base plate

- Chip filter removes coarse components from the coolant

- Robust, thick-walled cast-iron column for excellent force absorption

- Solid base plate with parallel T-slots, precision surface finish

- Optional footswitch available for toggling between right-handed/left-handed run and for thread tapping (Article no. 3050032)

OPTIdrill DH 35V

- Continuously adjustable speed control

- Pitch deactivation

- Easily readable digital display

- Digitally adjustable drilling and thread depth

- Digital zero point adjustable

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.

Specifications

| Info | |

|---|---|

| Brand | OPTIMUM |

| Dimensions and weights | |

|---|---|

| Weight | 365 Kg |

| Column diameter | 115 mm |

| Length x width x height | 860 x 474 x 2175 mm |

| Electrical Data | |

|---|---|

| Electrical connection | 400 V / 3 Ph ~50 Hz |

| Motor output | 2.2 kW |

| Drilling performance | |

|---|---|

| Drilling performance in steel | Ø 35 mm |

| Continuous drilling performance steel | Ø 26 mm |

| Thread tapping steel | M 24 |

| Spindle | |

|---|---|

| Spindle sleeve stroke | 125 mm |

| Spindle holder | MT 4 |

| Throat | 285 mm |

| Spindle sleeve feed | 3 speeds: 0.05-0.15 mm/rev |

| Rotational speeds | |

|---|---|

| Spindle speeds | 30 - 2 950 rpm |

| Number of speeds | 4 speeds, electronically controlled |

| Drilling table | |

|---|---|

| Drilling table workspace L x W | 400 x 420 mm |

| Drill table rotation/lateral pivot | 360° / ± 90° |

| Clearance spindle - drilling table | 65 - 800 mm |

| Drilling Table T-slot size/distance/amount | 14 mm / 150 mm / 2 |

| Machine base | |

|---|---|

| Clearance spindle - machine base | max. 1 217 mm |