Technical Specifications

Laser classification

Class 4 Laser system, possibility to switch in Class 1 for integration on a station or equipped with Mini inline module.

Monobloc design, easy integration

No sensitive cable connections in the system integration.

Thanks to its integrated HMI display, it provides access to self-diagnostic, updates, history of faults, maintenance functions, and simplifies the implementation and visualization of tasks for the operator.

Highly communicative laser

CO2 laser marker is compatible with a wide range of communication protocols: Ethernet TCP/IP, RS232, standard 8I/ 80, Dedicated I/O via DB-37 and optional industrial communication protocols like Profinet & Ethernet IP.

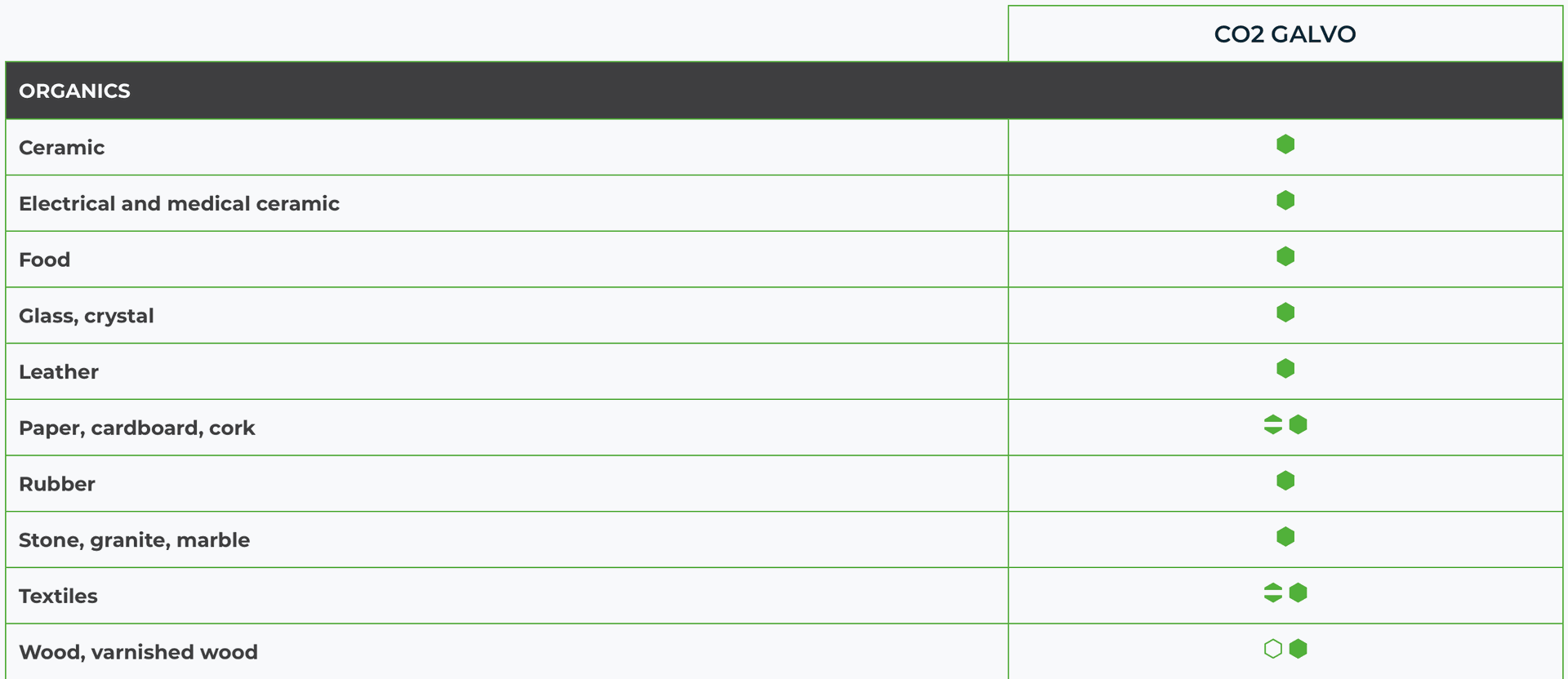

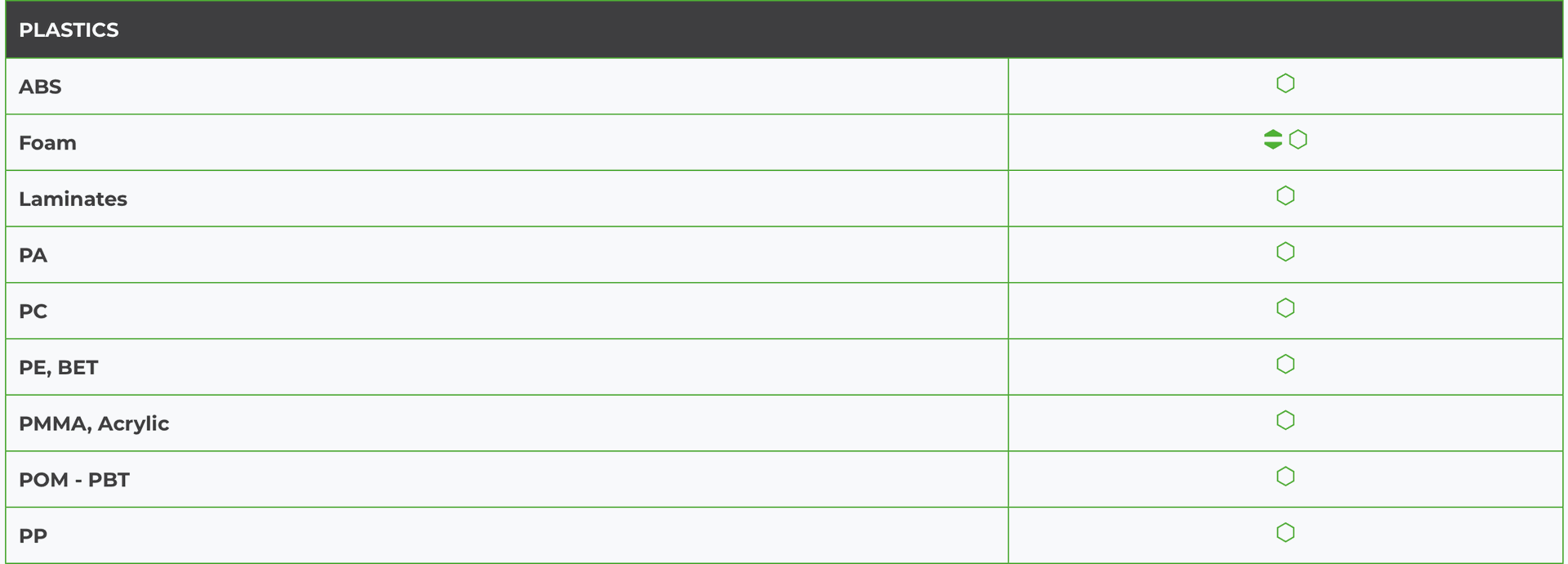

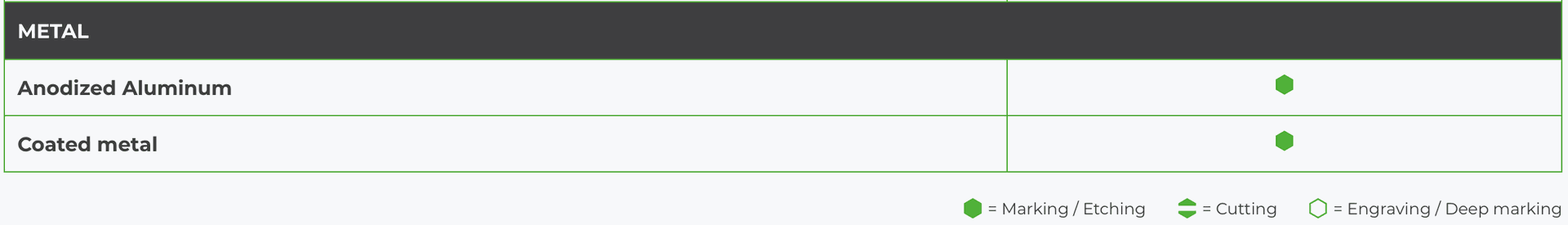

Marking possibilities

Engraving on organic materials, such as paper, cardboard, wood, leather, and engraving on transparent plastics.

Also Direct Markings on fruits and vegetables.

Durable laser system

- Working temperature up to 104°F, 40°C,

- Built-in and reusable filter for air cooling,

- Protection against scratches and deposits.

General

Wavelength

10600 nm

Available power version

30 W

Key functions

Process automation

Industrial Ethernet Networks

Safety Performance Level d

Embedded intelligence

Autonomous

Programmable by PLC

No PC required

Traceability Management

The Wood Marking Machine

Operating without materials, this integrated CO2 laser engraver directly marks the wood, without altering of the quality of the material.

Laser marking of wood does not generate chips, but only smoke, gases, and dust which can be safely evacuated by an extraction system.

There are many marking possibilities on wood which can be obtained by adjusting the speed or the power of the CO2 laser.

The marking color can vary from dark brown, through lighter shades of brown, to white.With high power, this marking on the fly laser can easily cut into the wood and thus create engravings with on all types of wood: natural, MDF, varnished, cork, chipboard, and precious woods.

Vision Manager – One Solution For Marking & Reading

This optional Vision manager kit helps you to read codes and texts in the marking process, to guarantee that the marking has been performed correctly and to ensure 100% traceability of your production:

- High efficiency: reading camera with lighting, auto-focus system and protective lens.

- Easy to install: You are just a few clicks away from complete control of 1D/2D codes and your text (OCR fonts).

- Grade analysis: control of code readability (Grade).

- Quality check of the marking: sending status information and history to the PLC, activating alarms, activating actuators to reject the faulty part.

This laser marker can handle more than 30 materials

Specifications

| Info | |

|---|---|

| Brand | Gravotech |

| Origin | FR |

| Technical Specs | |

|---|---|

| Marking Area - Lens | F100 (70x70mm) or F150 (100x100mm) or F200 (140x140mm) or F300 (210x210mm) |

| Power | 30W |

| Frequency | CW laser (Continous Wave) |

| Operating Temperature | 10 to 40°C (50 to 104 F) |

| Laser safety classification | Class 4 |

| Power consumption rate | 1000W |

| Humidity level | 10-85% |

| Rated voltage | 100 - 240 V AC |

| Scan Speed | Up to 10000 mm/s (393.7 in/s) |

| Display | Integrated screen with control panel for: REAL-TIME SUPERVISION, EASY DIAGNOSIS, SOFTWARE UPDATES, MEMORY BACK-UP… |

| Marking Specifications | +60 Gravotech fonts, Possible to convert User & TTF fonts, All formats of barcode and 2D codes, Logos |

| Fieldbus | PROFINET or ETHERNET IP |

| Dimensions and weights | |

|---|---|

| Weight | 24 Kg |

| Marking Specs | |

|---|---|

| Communication interfaces (standard) | Ethernet TCP/IP; Terminal block 8I / 8O; Laser Safety Dedicated I/O; RS232; USB |